AASMIS is the Management Information System of an AAS (Autoconer

Automation System) developed by Zircon Infotech for a spinning industries.

AASMIS is an excellent monitoring system to take rapid actions and

decisions against abnormal drums, material (higher/lower cuts), Men (where red and

yellow lights is higher) and etc.The system generates lot wise production details,

machine wise production details, abnormal drums on the basis of sigma values and

the average value, long term analysis for a machine, and machine wise breakup of

a parameter etc.

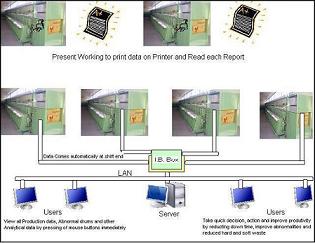

AAS interface MIC of Schlafhorst 238 Autoconer with computer and fetch the production

data at the end of each shift. After that AASMIS will generate various types of

MIS reports on the basis of cuts, efficiency, red lights,

losses and productions etc.

Generally the particals of cotton or polyester damaged the working of thermal printer

and user does not get the printout of shift end report. In this case user noted

the reading at the MIC on the register and compared the result. If the printer is

in working position then also user does not get the printout of all parameters,

because to study of all parameters it required much more time as well as the cost

of thermal paper is also costly. Not only the above reasons but apart from them

lot of reasons are there to utilize this system at industry.

AASMIS helps to Industry to segregate material where quality of yarn is not good

e.g. industry can separate material of particular drum where no. of cuts is very

high or very low.

By monitoring above reports and taking appropriate actions, industries can automatically

improve their efficiency. As per the actions and material of yarn it may exceed

beyond 82%.

After few years when the existing autoconers does not work with

full efficiency and the efficiency of production godown slowly slowly then industry

has required to either upgrading their autoconers or purchase new autoconer machine

to produce more yarns. But if the industries installed the Autconer Automation System

then may be he does not required to purchase new autoconers immediately and get

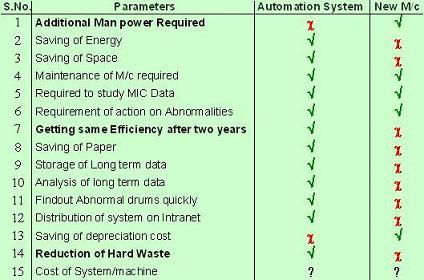

execute their machines with full efficiency upto long time. We are given a comparision

between Autoconer Automation System with new Autoconer machine below:

Comparision 1 :

Comparision 2 :

Suppose a Industry have 10 no.s of Autoconers and improve their efficiency upto

5% they they have save the total production cost as follows :

Lets assume that each autoconer produce 2000 Kg of yarn per day and the

production cost involve on autoconer is Rs. 10/Kg.

Then industry save 2000kg * Rs. 10kg * 5% * 10 autoconers * 365 days = Rs. 3650000

in a year

If industry assume that he does not save Rs. 10/kg production cost at autocoro machine

due to their inner infrastructure and they can saved only Rs. 2/kg then the savings

are: Rs.730000 per year

Comparision 3:

Suppose, the industry assume that he can not achieved the efficiency upto 5% and

does not save the production cost still but he can cut down the reduction waste

by 0.1% then he can saved the cost as follows :

Lets us assume that the cost of yarn is Rs. 80/kg and industry produced 2000kg of

yarn / day / autoconer Saving by Reduction waste : 10 autocoro * 2000 kg * 0.1%

* Rs 80/kg * 365 days = Rs. 584000 per year.

Industry can get this savings every year with putting only very less efforts

to viewing the production and abnormal drum reports and take the actions accordingly

at their chair.

1.Saving in Thermal Paper Cost: Every Autoconer prints data for 60 drums for all

30 paramete per shift and it takes 3 meters of roll. It costs Rs. 3 per meter. The

total paper cost for 8 Autoconers in one year = 8 Autoconers x 3 shifts x 365 days

x 3 meters x Rs. 3 per meter = Rs. 78,840.

2.Increased Earning due to Increase in Efficiency: It has been noticed that after

installation of automatic reporting system, the efficiency increased by as much

as 7-8 %. Even if we expect a modest figure of 1%, which is not at all difficult

to achieve, this will lead to a increased production of 1%.Each Autoconer produces

2000 Kg. of yarn @Rs. 10 per Kg. This means a daily production of Rs.20,000 per

Autoconer per day. The increased earning due 1% efficiency increase will be only

Rs. 200 per day.For 8 Autoconers and for 365 days, the additional earnings will

be Rs. 200 x 8 Autoconers x 365 days =Rs. 5,84,000.sp;

3.Reduction in Hard Waste: A nominal reduction of hard waste to final production

ratio by 0.1 % gives us asaving as follows Rs.80 per Kg x 0.1% x 2000 Kg x 8 Autoconers

x 365 days = Rs.4,67,200.

4.Reduction in manpower Costs: Since this automatic system saves the cost of 1 persons

@Rs.10,000 per month, the annual saving is Rs.10000 x 1 persons x 12 months = Rs.

1,20,000.