|

After few years when the existing autoconers does not work with

full efficiency and the efficiency of production godown slowly slowly then industry

has required to either upgrading their autoconers or purchase new autoconer machine

to produce more yarns. But if the industries installed the Autconer Automation System

then may be he does not required to purchase new autoconers immediately and get

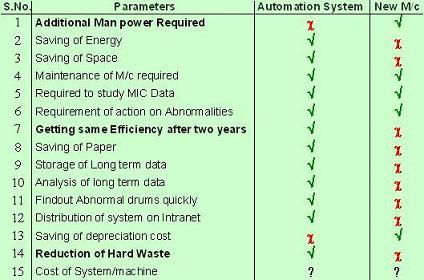

execute their machines with full efficiency upto long time. We are given a comparision

between Autoconer Automation System with new Autoconer machine below:

Comparision 1 :

Comparision 2 :

Suppose a Industry

have 10 no.s of Autoconers and improve their efficiency upto 5% they they have save

the total production cost as follows :

Lets assume that each autoconer produce 2000 Kg of yarn per day and the

production cost involve on autoconer is Rs. 10/Kg.

Then industry save 2000kg * Rs. 10kg * 5% * 10 autoconers * 365 days = Rs. 3650000

in a year

If industry assume that he does not save Rs. 10/kg production cost at autocoro machine

due to their inner infrastructure and they can saved only Rs. 2/kg then the savings

are: Rs.730000 per year

Comparision 3:

Suppose, the industry assume that he can not achieved the efficiency upto 5% and

does not save the production cost still but he can cut down the reduction waste

by 0.1% then he can saved the cost as follows :

Lets us assume that the cost of yarn is Rs. 80/kg and industry produced 2000kg of

yarn / day / autoconer Saving by Reduction waste : 10 autocoro * 2000 kg * 0.1%

* Rs 80/kg * 365 days = Rs. 584000 per year.

Industry can get this savings every year with putting only very less efforts

to viewing the production and abnormal drum reports and take the actions accordingly

at their chair.

Benefits....

Features....

Cost of Saving...

|